When molding large parts, the little details become even more important. At Integrated Value Services Ltd, the right infrastructure, innovation and expertise come together every day to produce high-quality, cost-efficient parts. Focusing on fit, form and function ensures we exceed our customers’ expectations and requirements throughout long-term part production. Today, we operate more than 30 large-ton plastic injection molding machines, ranging from 1,000 to 3,500 tons, at our facilities in the United States, Mexico and China.

PUTTING PROJECTS IN MOTION

Different processes offer different advantages. Here are the ways we can optimize your large part molding project.

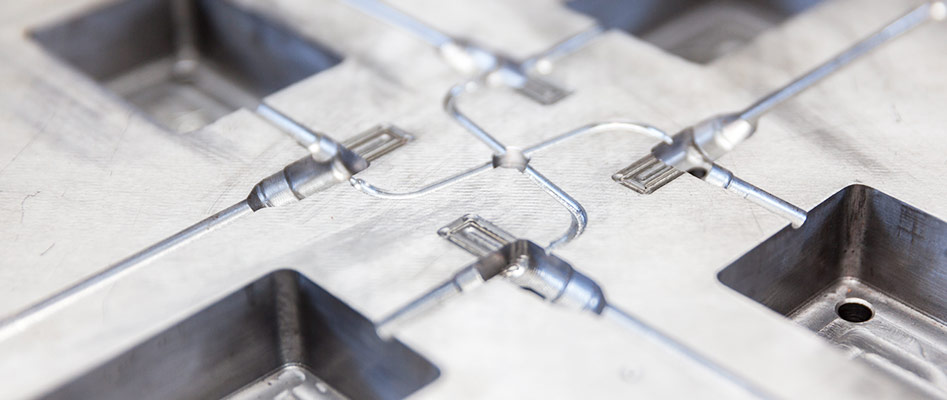

GAS ASSIST MOLDING

Assist the molding process with strategically timed and incorporated pressurized gas to make stronger and more aesthetically pleasing parts.

MOLDED-IN COLOR

Produce parts with vibrant, long-lasting color without painting, and eliminate quality issues due to scratching or peeling.

SECONDARY OPERATIONS

Provide fully labeled, decorated and assembled injection molded parts and sub-assemblies through value-added processes.

INSERT MOLDING

Create a strongly bonded, integrated part by molding material around an insert piece for enhanced component reliability.

Design for Manufacturability

This robust process employs strategic preparation and applies strict quality controls to ensure a consistent product output—and a competitive advantage for customers. DFM is the cornerstone for every project Integrated Value Services Ltd undertakes because the design and engineering process is critical to success.

Materials Selection

When developing a new part, determining the right material is essential. As part of the DFM process, understanding the requirements and performance characteristics of the part allows Integrated Value Services Ltd to determine the best material for your project.

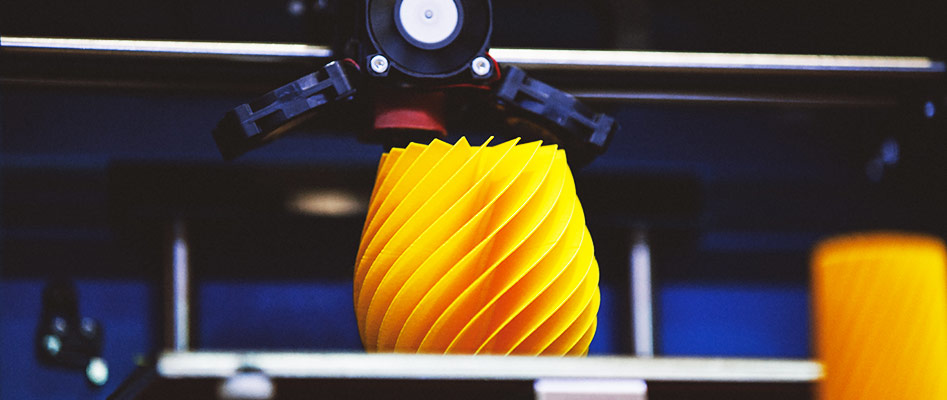

Tooling

A successful part starts with a well-designed mold. This complex and precise process determines part manufacturability and lifecycle costs, and takes into account the key components of mold design while adhering to a part’s unique specifications

Metrology

Our commitment to quality is based on stringent guidelines and blends seamlessly with our deep manufacturing knowledge and experience.

Case Study: Design for Manufacturability

Thorough Preparation Leads to a Better End Product

Developing a new product involves many moving parts, in both a planning and a manufacturing sense. It includes multiple teams and checkpoints designed to ensure a flawless end product. Preparation is a vital part of the product development process, as it sets up the rest of the project for success. Read how Integrated Value Services Ltd can help bring your product development project to life.